The Baltimore manufacturing unit contracted to make Johnson & Johnson’s COVID-19 vaccine was soiled, did not observe correct manufacturing procedures and had poorly skilled employees, leading to contamination of fabric that was going to be put within the photographs, U.S. regulators stated Wednesday.The Meals and Drug Administration launched a press release and a 13-page report detailing findings from its latest inspection of the now-idle Emergent BioSciences manufacturing unit. Company inspectors stated a batch of bulk drug substance for J&J’s single-shot vaccine was contaminated with materials used to make COVID-19 vaccines for an additional Emergent shopper, AstraZeneca. That batch, reportedly sufficient to make about 15 million J&J vaccine doses, needed to be thrown out.Different issues cited within the inspection report had been peeling paint, black and brown residue on flooring and partitions within the manufacturing unit, insufficient cleansing and staff not following procedures to stop contamination.Nothing made on the manufacturing unit for J&J has been distributed, the FDA famous. The almost 8 million doses of J&J vaccine given within the U.S. got here from Europe.Each Emergent and Johnson & Johnson stated Wednesday that they’re working to repair the issues as rapidly as potential. After high quality issues surfaced late final month, J&J took management of the manufacturing unit. The Biden administration now’s working to maneuver AstraZeneca vaccine manufacturing to a different manufacturing unit. AstraZeneca’s vaccine isn’t but licensed in the usThe Baltimore manufacturing unit halted all manufacturing late final week on the request of the FDA. The company hasn’t given emergency approval to the manufacturing unit, which is required earlier than any vaccine materials made there may be distributed.All the majority vaccine substance Emergent has made, plus early batches made there after which put in vials and packaged by different J&J contractors, are being saved and can endure further testing by the FDA, the company stated.”We’re doing all the things we will to make sure that the COVID-19 vaccines which are given to the folks of this nation have met the company’s excessive requirements for high quality, security and effectiveness,” the FDA stated.For the time being, use of the J&J vaccine is on maintain within the U.S. as authorities well being officers examine its potential connection to very uncommon blood clots. Their determination on whether or not to permit the vaccine to be given may come Friday. On Tuesday, the European Medicines Company’s security committee stated its assessment discovered the blood clots are a really uncommon facet impact however that the J&J vaccine’s advantages outweigh that threat. Emergent, a little-known drug manufacturing contractor, was granted a significant position within the Trump administration’s response to the coronavirus. The corporate has been repeatedly cited by the FDA for issues starting from poorly skilled staff to cracked vials and mould round one in every of its services, in response to data obtained by The Related Press.FDA inspectors began checking the Emergent manufacturing unit in Baltimore on April 12 and completed their investigation on Tuesday. The inspectors reviewed safety digital camera footage that confirmed staff carrying unsealed baggage of medical waste round within the manufacturing unit, with the luggage touching supplies prepared for use to make vaccine batches. The footage additionally confirmed staff transferring between manufacturing areas for the 2 vaccines with out documenting whether or not they modified protecting robes and showered in between, as required.The inspection report famous that Emergent did not sufficiently examine the contamination of the later-discarded J&J batch and did not seem to have achieved any further cleansing after the contamination was found.”There is no such thing as a assurance that different batches haven’t been topic to cross-contamination,” the report said.It additionally famous that the manufacturing unit had insufficient procedures for assuring that the vaccine substance met all high quality and purity necessities.It is unclear how lengthy it would take the businesses to resolve all the issues on the manufacturing unit, referred to as Bayview.J&J has pledged to supply 100 million doses for the U.S. by the top of Could and 1 billion doses globally by the top of the 12 months.”Proper now, we will not speculate on any potential impression this might have on the timing of our vaccine deliveries,” J&J stated in a press release.___The Related Press Well being and Science Division receives assist from the Howard Hughes Medical Institute’s Division of Science Schooling. The AP is solely chargeable for all content material.

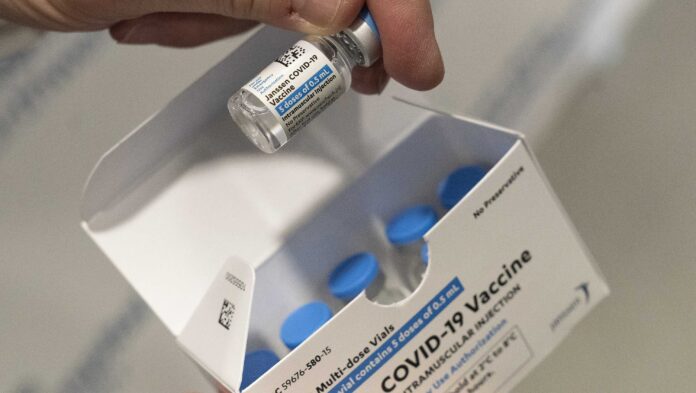

The Baltimore manufacturing unit contracted to make Johnson & Johnson’s COVID-19 vaccine was soiled, did not observe correct manufacturing procedures and had poorly skilled employees, leading to contamination of fabric that was going to be put within the photographs, U.S. regulators stated Wednesday.

The Meals and Drug Administration launched a press release and a 13-page report detailing findings from its latest inspection of the now-idle Emergent BioSciences manufacturing unit.

Commercial

Company inspectors stated a batch of bulk drug substance for J&J’s single-shot vaccine was contaminated with materials used to make COVID-19 vaccines for an additional Emergent shopper, AstraZeneca. That batch, reportedly sufficient to make about 15 million J&J vaccine doses, needed to be thrown out.

Different issues cited within the inspection report had been peeling paint, black and brown residue on flooring and partitions within the manufacturing unit, insufficient cleansing and staff not following procedures to stop contamination.

Nothing made on the manufacturing unit for J&J has been distributed, the FDA famous. The almost 8 million doses of J&J vaccine given within the U.S. got here from Europe.

Each Emergent and Johnson & Johnson stated Wednesday that they’re working to repair the issues as rapidly as potential.

After high quality issues surfaced late final month, J&J took management of the manufacturing unit. The Biden administration now’s working to maneuver AstraZeneca vaccine manufacturing to a different manufacturing unit. AstraZeneca’s vaccine isn’t but licensed within the U.S.

The Baltimore manufacturing unit halted all manufacturing late final week on the request of the FDA. The company hasn’t given emergency approval to the manufacturing unit, which is required earlier than any vaccine materials made there may be distributed.

All the majority vaccine substance Emergent has made, plus early batches made there after which put in vials and packaged by different J&J contractors, are being saved and can endure further testing by the FDA, the company stated.

“We’re doing all the things we will to make sure that the COVID-19 vaccines which are given to the folks of this nation have met the company’s excessive requirements for high quality, security and effectiveness,” the FDA stated.

For the time being, use of the J&J vaccine is on maintain within the U.S. as authorities well being officers examine its potential connection to very uncommon blood clots. Their determination on whether or not to permit the vaccine to be given may come Friday.

On Tuesday, the European Medicines Company’s security committee stated its assessment discovered the blood clots are a really uncommon facet impact however that the J&J vaccine’s advantages outweigh that threat.

Emergent, a little-known drug manufacturing contractor, was granted a significant position within the Trump administration’s response to the coronavirus. The corporate has been repeatedly cited by the FDA for issues starting from poorly skilled staff to cracked vials and mould round one in every of its services, in response to data obtained by The Related Press.

FDA inspectors began checking the Emergent manufacturing unit in Baltimore on April 12 and completed their investigation on Tuesday.

The inspectors reviewed safety digital camera footage that confirmed staff carrying unsealed baggage of medical waste round within the manufacturing unit, with the luggage touching supplies prepared for use to make vaccine batches. The footage additionally confirmed staff transferring between manufacturing areas for the 2 vaccines with out documenting whether or not they modified protecting robes and showered in between, as required.

The inspection report famous that Emergent did not sufficiently examine the contamination of the later-discarded J&J batch and did not seem to have achieved any further cleansing after the contamination was found.

“There is no such thing as a assurance that different batches haven’t been topic to cross-contamination,” the report said.

It additionally famous that the manufacturing unit had insufficient procedures for assuring that the vaccine substance met all high quality and purity necessities.

It is unclear how lengthy it would take the businesses to resolve all the issues on the manufacturing unit, referred to as Bayview.

J&J has pledged to supply 100 million doses for the U.S. by the top of Could and 1 billion doses globally by the top of the 12 months.

“Proper now, we will not speculate on any potential impression this might have on the timing of our vaccine deliveries,” J&J stated in a press release.

___

The Related Press Well being and Science Division receives assist from the Howard Hughes Medical Institute’s Division of Science Schooling. The AP is solely chargeable for all content material.